Analysis of Technical Pathways for Organic Waste Gas Treatment and Environmental Compliance in the Disassembly Process of Automotive Lithium Batteries

With the rapid development of the new energy vehicle industry, lithium batteries, as the core power source, have increasingly drawn attention to environmental issues during their recycling and disassembly processes. Particularly during the disassembly of lithium batteries, the volatilization of organic substances such as electrolytes and binders can produce a large amount of volatile organic compounds (VOCs). If not handled properly, this can cause serious harm to the environment and human health. Therefore, how to efficiently treat these organic waste gases and ensure that their emissions comply with national and local environmental protection regulations has become a key issue that the lithium battery recycling industry urgently needs to address. This article will explore the technical pathways for treating organic waste gases during the disassembly of automotive lithium batteries in conjunction with national and local environmental protection regulations, and introduce the technical advantages of Megaunity Environmental Protection in this field.

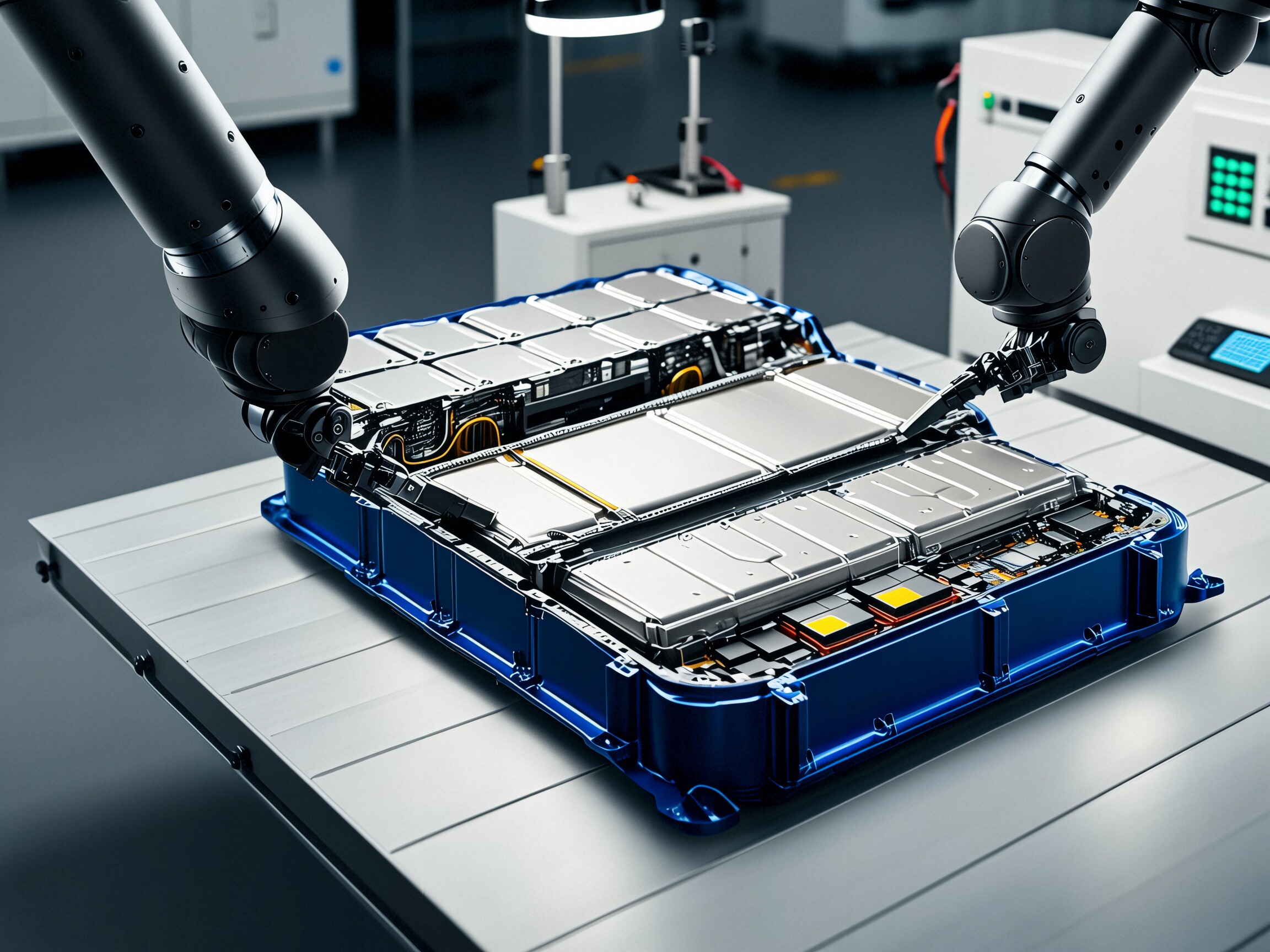

Sources and Characteristics of Organic Waste Gases in the Disassembly of Lithium Batteries

During the disassembly of lithium batteries, organic waste gases mainly originate from the following aspects:

1. Volatilization of Electrolyte:The electrolyte of lithium batteries is usually composed of carbonate organic solvents (such as ethylene carbonate, dimethyl carbonate, etc.) and lithium salts, which are prone to volatilization and form VOCs during the disassembly process.

2. Decomposition of Binders:Binders (such as PVDF) in the positive and negative electrode materials may decompose and produce organic waste gases under high temperatures or mechanical action.

3. Pyrolysis of Plastic Components:The battery casing and internal plastic components may release harmful gases such as benzene and aldehydes when heated during the disassembly process.

These organic waste gases are characterized by complex components, large concentration fluctuations, and high toxicity. If directly discharged, they will not only pollute the atmospheric environment but may also harm the human respiratory and nervous systems. Therefore, effective treatment measures must be taken to ensure that waste gas emissions meet standards.

Technical Pathways for Treating Organic Waste Gases

For the organic waste gases generated during the disassembly of lithium batteries, the mainstream treatment technologies currently include adsorption, combustion, and condensation. Based on the characteristics of lithium battery waste gases, the following combined processes are recommended:

1. Pre-treatment Stage:Efficient Collection and Condensation Recovery

- Closed Collection System: Set up a negative pressure closed system in the disassembly workshop to ensure that waste gases do not escape unorganized. At the same time, use local exhaust hoods to collect high-concentration waste gases at specific points.

- Condensation Recovery: Use condensers to condense and recover high-boiling organic solvents (such as carbonates) from waste gases, which not only reduces the treatment load but also achieves resource utilization.

2. Core Treatment Stage:Adsorption Concentration + Catalytic Combustion

- Adsorption Concentration: Use activated carbon or zeolite wheels to adsorb and concentrate low-concentration waste gases, raising the waste gas concentration to the range required for catalytic combustion (usually 1000-4000 mg/m³).

-Catalytic Combustion: Introduce the concentrated waste gases into a catalytic combustion device, where organic substances are oxidized and decomposed into CO₂ and H₂O at lower temperatures under the action of catalysts.

Megaunity's Technical Advantages and Business Practices

As a veteran enterprise in the field of industrial waste gas treatment, Megaunity has been established for over 30 years and has accumulated rich experience in treating organic waste gases. In response to the characteristics of waste gases from lithium battery disassembly, Megaunity has launched customized VOCs treatment combined processes with the following technical advantages:

1. High Efficiency Purification:Using efficient adsorption materials and high-quality catalysts to ensure that the waste gas purification efficiency remains stable and meets standards.

2. Energy Saving and Consumption Reduction:By using a waste heat recovery system, the heat generated from catalytic combustion is used to preheat the incoming air, significantly reducing operational energy consumption.

3. Intelligent Control:Equipped with advanced intelligent control systems and online monitoring equipment to achieve automated operation and remote monitoring of the entire waste gas treatment process.

The Megaunity team possesses deep professional knowledge and can accurately formulate personalized design plans based on the waste gas characteristics of the lithium battery disassembly industry. Moreover, Megaunity introduces advanced production equipment and processes in the production phase, strictly controlling the quality of every component to ensure the stable performance of the waste gas treatment system. In terms of construction, Megaunity has complete qualifications and an experienced construction team, who have been tempered by multiple large-scale projects and are familiar with strategies to address various construction challenges. From preliminary site surveys to mid-term construction installation and later debugging and maintenance, they can ensure a smooth and efficient project progression.

The treatment of organic waste gas generated during the disassembly of lithium batteries is a complex system engineering project that requires comprehensive approaches from source control, process collection to end treatment. Megaunity's professional technology and services can effectively achieve emissions that meet standards, supporting the green and sustainable development of the lithium battery recycling industry. In the future, with the increasing strictness of environmental protection regulations and continuous technological advancements, Megaunity will continue to uphold the concept of "creating value for customers" and provide customers with more efficient and reliable waste gas treatment solutions, contributing to the fight for blue skies.

Industrial Air Handling System Solutions Provider

Tel:400-860-5288

E-mail: marketing@megaunity.com

Address:

No.300, Dongxin Road, Wuzhong District, Suzhou, Jiangsu, China

No.8, Shuzi 3rd Road, DD Port, Dalian Jinpu New Area, Liaoning, China

Copyright © 2022 Megaunity Air System Co., Ltd. All RIght Servered